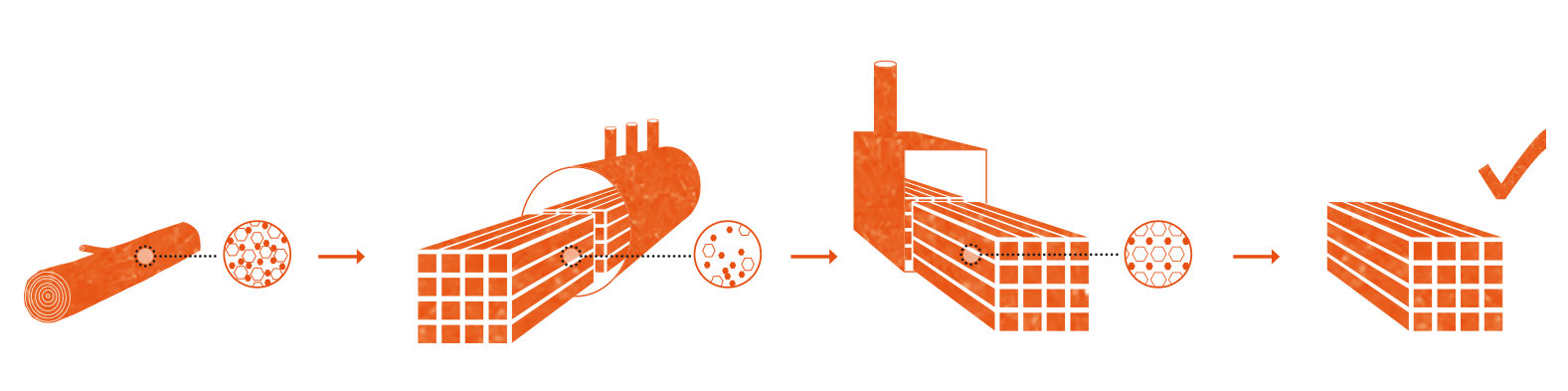

Fast-growing wood types from FSC and OLB certified forests undergo the patented and fully developed process before they leave the factory as Platowood. Platonising (hydrothermal modification process) is a proprietary process, performed in our factory located at Industrial Park Kleefse Waard. Where other processes often only consist of drying and heating, to up to 200 to 230 degrees Celsius, the unique Platowood process consists of three steps, during which water and heat are used to reinforce the wood. Platonising under relatively low temperatures is the best method, as the wood maintains its cellular structure – and with it, all of its good characteristics.

Hydrothermolysis - Unique in the world

Untreated wood is heated to up to 170⁰C in an autoclave, using steam and increased pressure. This process takes about 30 to 60 minutes. The duration depends on the dimensions and wood type.

Drying

Afterwards, the wood is carefully and gradually dried, to make sure it does not crack.

Curing

Once the wood dries to a moisture content of about 8%, it is moved into the oven. The wood is then heated again to up to 180⁰C in dry conditions, without oxygen. Because of the relatively low temperature, the wood maintains its elasticity, making it excellently processable.

The process is based on scientific research. Simply put, the process comes down to cooking, drying and baking. During these steps, new and stable compounds form inside the wood. After platonising, the wood absorbs less moisture, which in turn decreases shrinkage and swelling. Later moulding is also prevented through the natural degradation of sugars – a feeding ground for moulds – in the wood. Read more about all benefits of Platowood here.

Excellently processable

After platonising, the wood can be processed normally. Processes like sawing, planing, milling and drilling have absolutely no influence on its durability. The wood is so dimensionally stable that it requires fewer fasteners, which leads to lower assembly and maintenance costs.