Stichting Collectief Soepel has developed a façade panel using a Platowood residual product: Fraké spacer slats. This modular cladding system can be adapted to the needs of both user and surroundings. The Fraké panel is a highly sustainable innovation — a product born from residual flow, transformed into multifunctional and aesthetic façade cladding.

Platowood’s Residual Stream

The spacer slats are part of the deliveries of Fraké wood to Platowood. They are placed between boards for ventilation and to prevent mould. The same slats are also necessary during the platonising process to ensure steam and heat reach every board evenly. As a result, they form an unavoidable residual stream.

During a visit to Platowood, the designers from Collectief Soepel were introduced to the large stacks of spacer slats — and immediately saw potential. They envisioned turning the waste stream into a meaningful and high-impact product.

From Waste to Refined Cladding

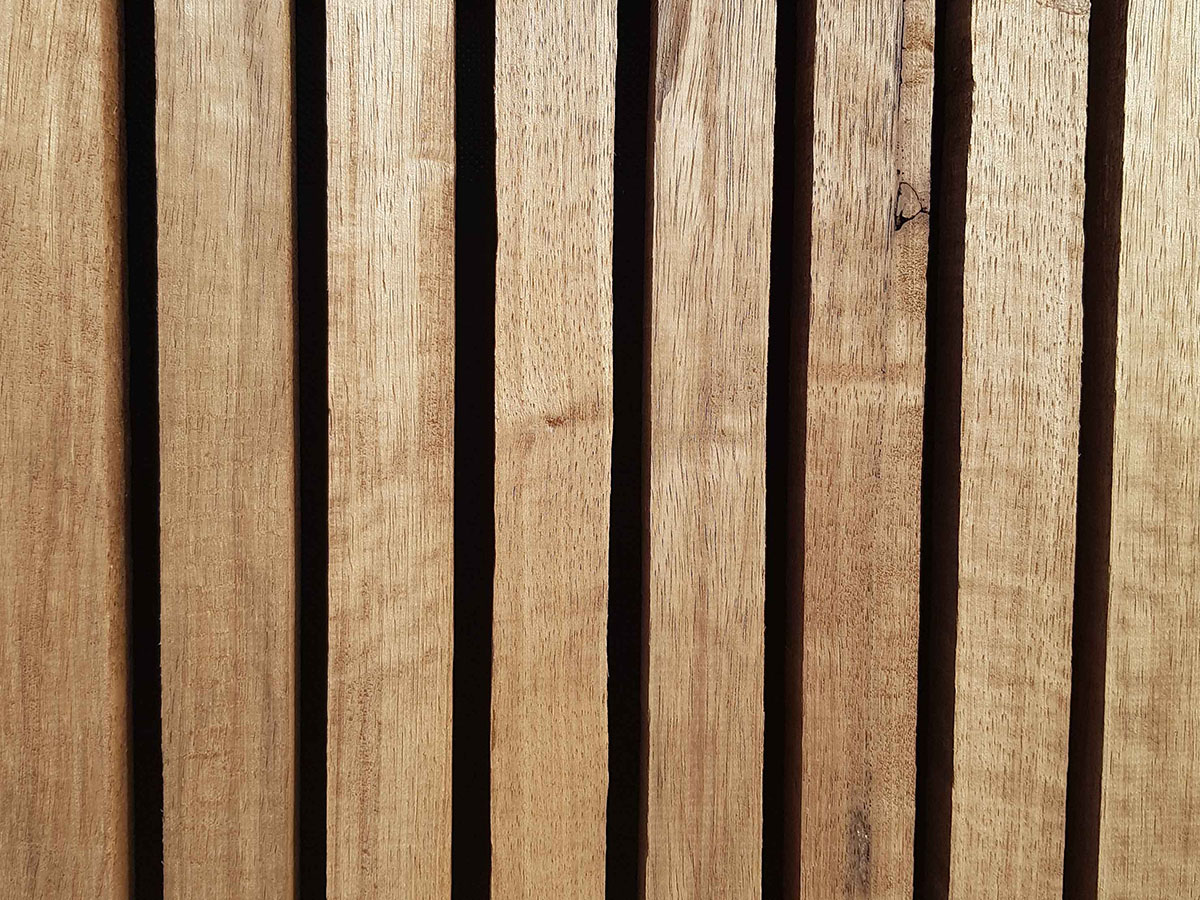

Approximately 70% of the slats received from Platowood can be used. Each piece is selected for usability, some are too brittle or warped. By planing one side of the slats, the natural beauty of the wood is revealed.

Each slat is unique in grain and imperfections. But when the panels are placed side-by-side on a larger scale, they create a rhythmic façade with a refined architectural look. For a product made from imperfect leftovers, the end result is remarkably clean and elegant.

Tiny House as test-case

The first Fraké panels were used on a Tiny House designed and built by Collectief Soepel. Around 50 panels (each made up of 40 slats) were used. With two more Tiny Houses in the pipeline, both slightly larger, another 150 panels are expected to be produced.

Product in Development

The first prototypes were made by hand — a time-intensive task taking up to half a day per 1.20 × 1.20 m panel. Collectief Soepel has since developed a mould, reducing production time to around 18 minutes per panel. Further improvements to the mould are planned to make the product more economically viable. They aim to invest in a new version soon to optimise the process.

Additionally, the designers see many other possibilities for Platowood’s spacer slats. The development of the Fraké panels marks the beginning of a sustainable collaboration between Platowood and Collectief Soepel — one that perfectly aligns with Platowood’s mission: minimal environmental impact and permanent CO₂ storage.